Re-designing with Amstrong® Ultra 900MCL brings:

- Over 50% weight reduction

- Lower material cost compared to compared to alternative materials and designs

- Significant CO₂ savings in raw material production

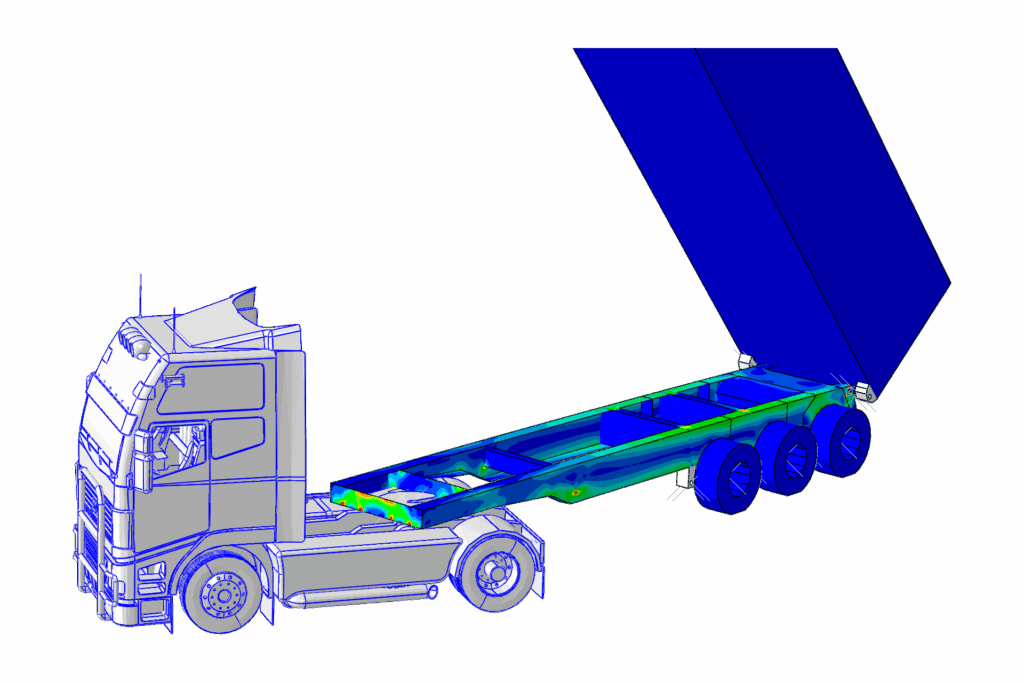

- Improved fatigue resistance

- Stable performance under tipping and inclined loading conditions

- Reduced deflection while maintaining required rigidity