Relia® is ArcelorMittal’s range of high hardness, wear-resistant steels, developed for applications where surface abrasion leads to premature wear and costly downtime.

With excellent hardness and toughness, Relia® helps extend the service life of equipment and components exposed to harsh operating environments such as mining, quarrying, construction machinery, and material handling systems.

Manufactured in Europe and available in various thicknesses and formats, Relia® ensures reliable performance and ease of processing — even for complex parts.

Why choose Relia®?

Relia® is designed for manufacturers who need strong, abrasion-resistant steel that can withstand repeated impact and friction.

High hardness levels

for longer wear life in abrasive environments

Available in a range

of thicknesses and dimensions for different wear protection needs

Supports conventional

cutting, bending and welding methods

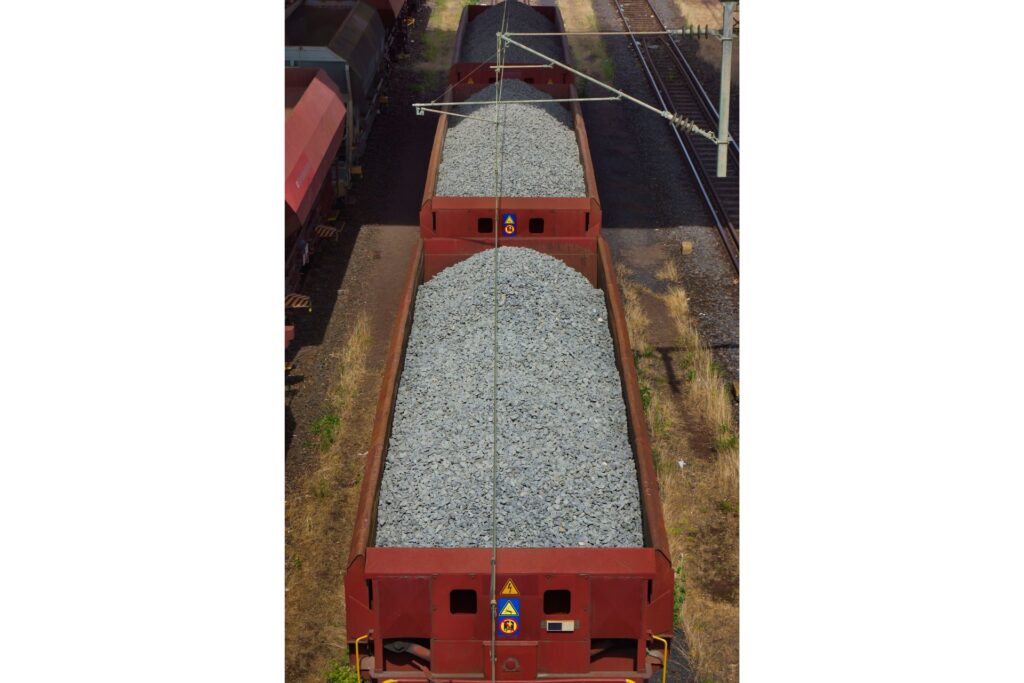

Suitable for machine parts

exposed to sand, gravel, rocks, or industrial and waste

Key benefits

Extended service life, even under severe abrasive conditions

Hover to discover

Relia®

Relia®

High hardness and impact toughness, balancing protection and resistance

Hover to discover

Lower lifecycle costs through better durability and performance

Hover to discover

Relia®

Many applications

Relia® steels find applications in a wide range of industries, from transportation to construction and beyond. Their strength, formability, and fatigue resistance make them valuable choices for demanding environments.

Available grades

| Relia® | Hardness level (HBW) | Thickness range (mm) | Consult us for thickness (mm) | Maximum width (mm) |

|---|---|---|---|---|

| Relia 400 | 370-430 | 5.0-8.0 | 2.0-4.0 | 1860 |

| Relia 450 | 420-480 | 5.0-8.0 | 2.0-4.0 | 1860 |

Download section

Get in touch with our team of experts

We’re ready to answer your questions. Get in touch and discover how Amstrong® can help you achieve your construction objectives.